Sustainable Packaging Ideas for Beauty Vending Machines

- Sustainable Packaging Ideas for Beauty Vending Machines

- Why sustainable packaging matters for Beauty Vending Machine operators

- Key principles for sustainable packaging in Beauty Vending Machine deployments

- Material choices: pros and cons for beauty vending packaging

- Design strategies to reduce packaging waste in Beauty Vending Machine systems

- Operational tactics enabled by smart vending for packaging sustainability

- Cost and environmental comparison: common packaging choices

- Regulatory and labeling considerations

- Customer experience: keeping beauty packaging attractive and functional

- Implementation roadmap for rolling out sustainable packaging in your Beauty Vending Machine fleet

- How IMT's smart vending solutions support sustainable packaging strategies

- Practical examples and quick wins for Beauty Vending Machine operators

- FAQ — Sustainable Packaging for Beauty Vending Machine

- Q: Can recyclable packaging jam a Beauty Vending Machine?

- Q: Are compostable packages a good option for vending?

- Q: How much can refillable cartridges reduce packaging costs?

- Q: What certifications should I look for when claiming sustainable packaging?

- Q: How does IMT help implement sustainable packaging in vending fleet?

- Sources and references

Sustainable Packaging Ideas for Beauty Vending Machines

Why sustainable packaging matters for Beauty Vending Machine operators

Consumers increasingly expect beauty products to be both high-quality and environmentally responsible. For operators and brands using a Beauty Vending Machine, packaging is not just about protecting a product — it influences consumer perception, operating costs, inventory dynamics, and compliance risk. Sustainable packaging reduces landfill waste, cuts material costs over time, and can improve sales by aligning with consumer values. Moreover, in a vending context, packaging choices affect machine touchscreen interactions, dispensing reliability, and storage density. Making the right choices requires balancing sustainability, durability, and vending compatibility.

Key principles for sustainable packaging in Beauty Vending Machine deployments

Use the Reduce-Reuse-Recycle hierarchy as a practical decision framework for packaging strategy in Beauty Vending Machine operations:

- Reduce: Minimize material volume and complexity. Smaller, lighter packages increase SKU density inside machines and reduce transport emissions.

- Reuse: Design refillable formats or reusable outer shells that are collected and refilled, particularly for higher-value cosmetics or tools dispensed from Beauty Vending Machine systems.

- Recycle: Choose materials that are widely recyclable or certified compostable in your operating regions, and label them clearly so consumers can dispose correctly.

Applying these principles helps vending operators improve margins through shipping and storage savings while meeting sustainability goals.

Material choices: pros and cons for beauty vending packaging

Material selection must consider fragility of contents (glass vs. cream), vending mechanics, consumer experience, and end-of-life. Common options include:

- Recycled paper & cardboard: Excellent for outer cartons and lightweight products; high recyclability and low cost, but needs protective inner packaging for liquids.

- PCR (Post-Consumer Recycled) plastic: Keeps plastics in circulation and improves recyclability of rigid containers; works well for pump bottles that must resist breakage during vending.

- Bioplastics / PLA: Compostable under industrial conditions and suitable for some single-use components, but local composting availability varies.

- Glass: High Quality feel and 100% recyclable, but heavier and breakable; may be better for stationary retail than some vending locations unless protective design is used.

- Refillable cartridges & concentrates: High sustainability potential by reducing single-use packaging volume; best paired with machines engineered for cartridge swapping and dispensing accuracy.

Design strategies to reduce packaging waste in Beauty Vending Machine systems

Thoughtful package design both protects products and optimizes vending operations. Strategies include:

- Modular packaging sizes standardized to machine columns to maximize SKU density and avoid wasted space.

- Reduced inner packaging: replace foam inserts with molded pulp or recyclable paper, saving material while maintaining protection.

- Refillable dispenser modules: for high-turnover items such as lotions or sanitizers, use sealed refill cartridges to eliminate many single-use containers.

- Flat-packed outer shells for seasonal or temporary promotions to reduce transport volume.

- Clear, minimal branding printed with soy-based inks to lower VOCs and improve recyclability of paper packaging.

Operational tactics enabled by smart vending for packaging sustainability

Operational practices play a large role in packaging footprint. Smart vending features that support sustainability include remote monitoring, inventory management, and automated restocking schedules. For example:

- Remote inventory monitoring avoids emergency trips and reduces partial-load shipments that increase per-unit transport emissions.

- Analytics-driven SKU optimization allows you to stock best-sellers in refillable formats and phase out low-turn items in single-use packaging.

- Predictive restocking supports bulk refill deliveries that use consolidated packaging and reduce packaging-to-product ratios.

These practices reduce packaging consumption and align with a circular approach to supply chains.

Cost and environmental comparison: common packaging choices

Below is a simplified comparison of common packaging options relevant to Beauty Vending Machine operators. Costs and recyclability vary by region and supplier; this table provides directional guidance.

| Packaging Type | Durability for Vending | End-of-Life | Relative Cost | Best Use Cases |

|---|---|---|---|---|

| Recycled Cardboard Box | Good for dry items and boxed sets; protects during dispensing | Widely recyclable (paper stream) | Low | Sheet masks, boxed beauty sets, refill pouches |

| PCR Rigid Plastic Bottle | High — resists breakage and moisture | Recyclable where PET/HDPE streams exist | Medium | Lotions, serums with pumps |

| PLA Compostable Tubes | Moderate — sensitive to heat; requires care in vending | Industrial composting required | Medium-High | Single-use masks, sample sachets in select markets |

| Reusable Dispenser Cartridge | Very high — designed for machine compatibility | Reduced waste; refill system returns reduce new packaging | Higher upfront, lower over lifecycle | High-turn lotion, sanitizer, liquid cosmetics |

Source notes: general industry cost and recyclability patterns; operators should request supplier-specific data. See source list at article end.

Regulatory and labeling considerations

Complying with local packaging and waste regulations is essential. Key actions include:

- Using correct recycling or compostability logos and ensuring claims (eg, compostable) are certified to recognized standards (such as ASTM D6400 or EN 13432).

- Providing clear disposal instructions on packaging, particularly for multi-material packages that require separation.

- Checking extended producer responsibility (EPR) rules in target markets — some jurisdictions require producer fees or take-back programs.

Failure to comply can lead to fines and reputational damage, counteracting any sustainability gains.

Customer experience: keeping beauty packaging attractive and functional

For beauty products, sensory experience matters. Sustainable packaging must still convey High Quality feel. Tactics include tactile recycled-paper sleeves, non-toxic inks, minimal windowing to show product, and elegant reusable outer shells. In vending, easy-open and reliable dispensing mechanism are crucial — avoid overly fragile or irregular shapes that jam vending spirals or drop-shelves. Test packaging prototypes extensively in your Beauty Vending Machine models before rollout.

Implementation roadmap for rolling out sustainable packaging in your Beauty Vending Machine fleet

- Audit current SKU packaging: quantify materials, weights, and end-of-life streams per SKU.

- Segment SKUs by turnover and sensitivity: high-turn items are best candidates for refillable cartridges; High Quality items need durable packaging.

- Pilot alternative formats in a subset of machines: monitor sales, machine reliability, and consumer feedback for 60–120 days.

- Refine supply chain: consolidate shipments, use flat-packed outer cartons, and partner with recyclers or take-back programs where possible.

- Scale successful pilots and publicize sustainability gains to consumers (labels on vending screens and product cards can increase perceived value).

How IMT's smart vending solutions support sustainable packaging strategies

Founded in 2014, IMT is committed to providing customers with customized smart vending machine solutions. IMT has an independent production plant of more than 10,000 square feet and a professional software and hardware development technical team. IMT's vending machines include functions such as automatic vending, remote monitoring, and inventory management — features that directly support sustainable packaging programs for Beauty Vending Machine deployments.

Key advantages IMT brings to sustainable packaging initiatives:

- Remote monitoring and inventory analytics: reduces emergency restocks and enables consolidated refill deliveries, lowering packaging and transport footprint.

- Custom machines and dispensing modules: allow deployment of refillable cartridges, bulk dispensers, or columns optimized for recycled or molded pulp packaging — decreasing single-use waste.

- Comprehensive product portfolio: IMT supplies Drink & Snack Vending Machine, Beauty & Nail Vending Machine, Locker Vending Machine, Coffee Vending Machine, Pharmacy Vending Machine and more, along with background management system software development and after-sales services. This breadth allows operators to standardize sustainability practices across machine types.

- Global reach: IMT products are exported to more than 100 countries and regions including the United States, Canada, France, Spain, Germany, Italy, and Russia, so best practices for packaging compliance and recycling can be applied across markets.

IMT's vision is to become the world's leading smart vending machine manufacturer. By pairing machine-level innovations with thoughtful packaging choices, operators can reduce waste, cut lifecycle costs, and meet evolving consumer expectations. Visit https://www.imtvending.com/ to learn more about IMT's vending solutions and explore customized options for sustainable Beauty Vending Machine projects.

Practical examples and quick wins for Beauty Vending Machine operators

Quick wins that can be implemented with modest investment:

- Switch to recycled-cardboard outer packaging for sheet masks and boxed kits.

- Introduce PCR bottles for lotions and ensure clear recycling labels.

- Deploy refillable dispensers for high-turn skincare products in high-traffic locations, paired with IMT remote monitoring to schedule efficient refills.

- Use molded pulp trays for fragile items to replace plastic inserts.

Over time, measure results: kilograms of packaging saved, reduction in collection frequency, and customer satisfaction. These KPIs help justify further investment.

FAQ — Sustainable Packaging for Beauty Vending Machine

Q: Can recyclable packaging jam a Beauty Vending Machine?

A: It can if the package is flimsy or inconsistent in shape. To avoid jams, standardize packaging dimensions and test prototypes in the machine model used. Use slight rigidity (eg, corrugated edges or PCR rigid bottles) for items that drop or spiral.

Q: Are compostable packages a good option for vending?

A: Compostable materials like PLA are promising, but they usually require industrial composting facilities which are not available everywhere. Evaluate local composting infrastructure and clearly label disposal instructions before choosing compostables for a Beauty Vending Machine.

Q: How much can refillable cartridges reduce packaging costs?

A: Upfront costs are higher for cartridge systems, but lifecycle analysis often shows savings for high-turn SKUs due to lower per-use packaging and transport costs. Specific ROI depends on turnover, refill logistics, and local labor costs — pilot testing is recommended.

Q: What certifications should I look for when claiming sustainable packaging?

A: Look for credible certifications such as FSC for paper, PCR content verification for plastics, ASTM D6400 / EN 13432 for compostables, and third-party recyclability verification programs. Accurate labeling is essential to avoid greenwashing.

Q: How does IMT help implement sustainable packaging in vending fleet?

A: IMT offers customizable dispensing modules, remote inventory and telemetry to optimize refill cycles, and engineering support to adapt packaging formats to machine mechanics. IMT also supports background management system software development and after-sales services to scale solutions across regions.

Want to reduce packaging waste and optimize your Beauty Vending Machine fleet? Contact IMT for a free consultation and demo of refillable, monitored vending solutions. Visit https://www.imtvending.com/ or contact our sales team to view product options including Drink & Snack Vending Machine, Beauty & Nail Vending Machine, Locker Vending Machine, Coffee Vending Machine, and Pharmacy Vending Machine.

Sources and references

- United Nations Environment Programme (UNEP) — reports on global plastic pollution and packaging waste trends.

- Ellen MacArthur Foundation — materials on the circular economy and packaging design for recyclability.

- McKinsey & Company — analyses of circular economy business cases and consumer attitudes to sustainable packaging.

- Industry recycling guidelines and certification standards: ASTM D6400, EN 13432, FSC guidance on recycled paper.

- Regional waste management authorities and municipal recycling program overviews for local infrastructure considerations.

Coffee Vending Machine Explained | IMT

How AI and IoT Enhance Pharmaceutical Vending Machines

How to Change Price on Snack Vending Machine for Max Profit - IMT

Tips for Wholesale soda and snack vending machine in France

For Factory

How about the warranty and after-sales services?

The product is guaranteed up to one year from purchased.We have professional after-sales team,About technical problem,our after-sales engineer will reply within 12 hours.

Can I see the machine data from my mobile phone?

Yes,we develop mobile phone app for the machine you can check the machine data such.

For Applications

How many machines do you provide? Is there a minimum order quantity?

We provide flexible cooperation options from single machines to large-volume orders. The specific minimum order quantity will be determined according to customer needs and project scale. Please consult our sales team for details.

Can the appearance and product combination of the machine be customized?

Yes, we can customize the appearance design and product combination of the machine according to the customer's brand image and market demand.

For Customization

How to ensure the quality of customized products?

We implement a strict quality management system, and all products undergo multiple testing processes to ensure that they meet high quality standards.

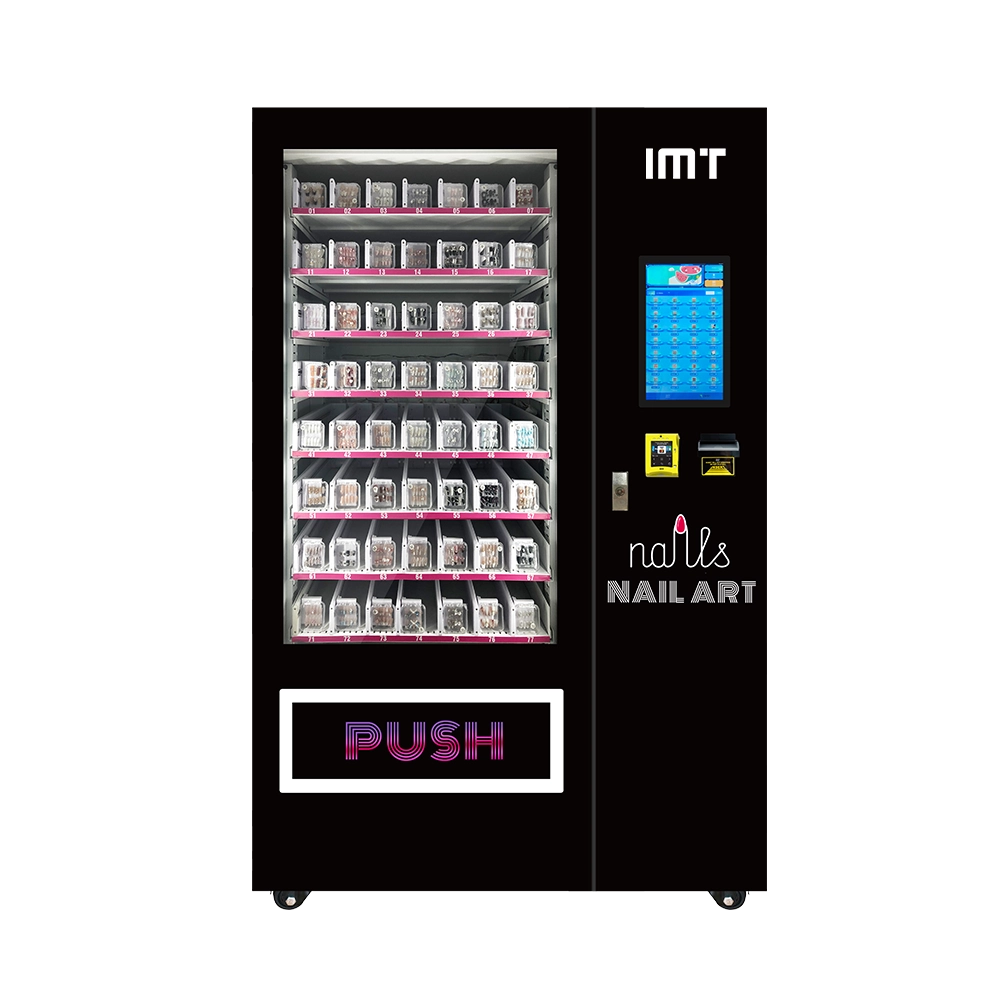

36 Slot Metal Keypad Thermostatic Automatic Beauty and Nail Vending Machine

Discover the IMT 36 Slot Metal Keypad Thermostatic Beauty and Nail Vending Machine. Designed for ultimate convenience, this innovative beauty vending machine offers a seamless shopping experience. Perfect for salons and spas, enhance your services today with this advanced nail vending machine.

60-Slot Thermostatic Vending Machine for Beauty, Nail & Apparel | Among Top Clothing Vending Machines for Sale

Discover the IMT 60-slot, 21.5-inch screen thermostatic beauty and nail vending machine. This state-of-the-art vending solution ensures that products are kept at optimum temperatures and offers unrivaled convenience. Ideal for beauty salons looking to innovate, this beauty and nail vending machine for sale enhances the customer experience and operational efficiency.

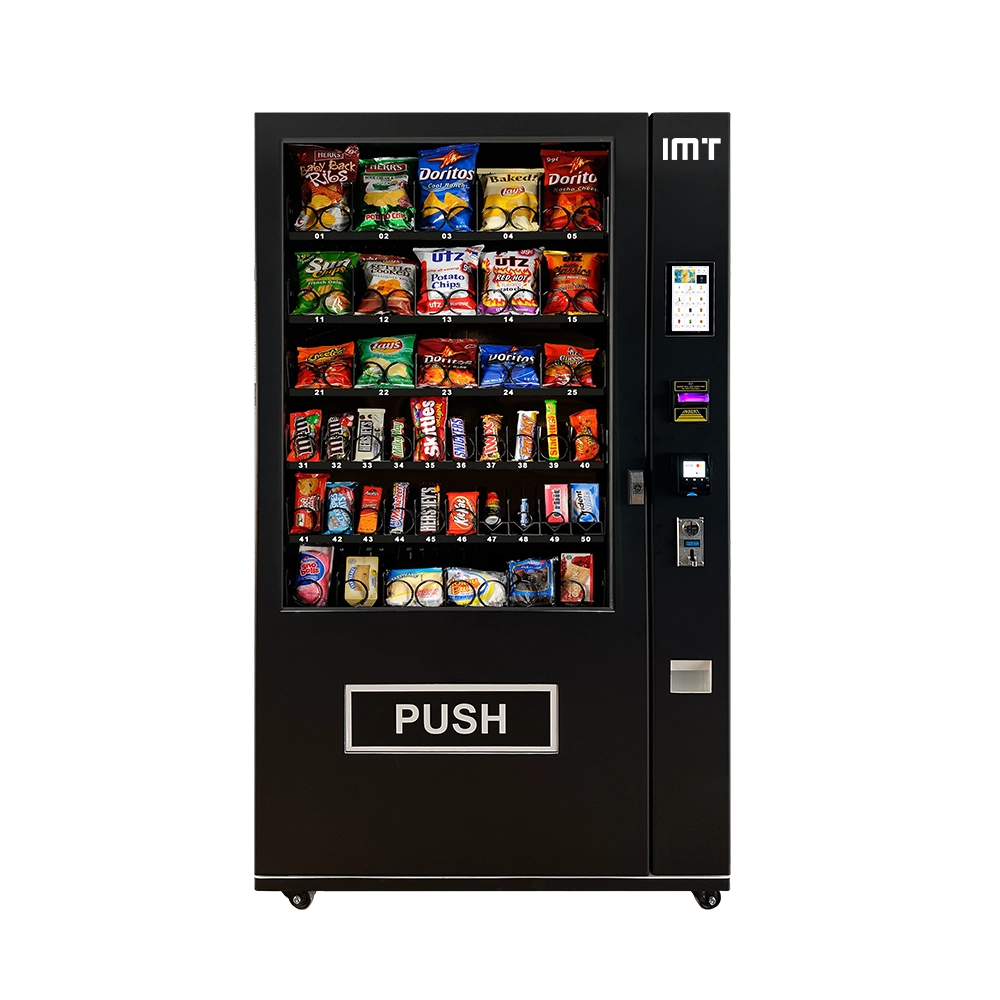

36 slots Small Screen Metal Keypad Drink Vending Machine

Introducing the IMT 36 Slot Small Screen Metal Keypad Drink Vending Machine. Perfect for any environment, this durable and reliable vending solution provides optimum access to beverages. Explore our range of vending machines for sale, designed to increase convenience and efficiency while improving your customers' refreshment options.

Interactive Touch Screen Vending Machines for Sale – 7.1-Inch Display, 60 Slots, Refrigerated for Drinks & Snacks

Discover the IMT 60 Slot 7.1" Screen Refrigerated Drink Snack Vending Machine, a top choice among snack vending machines for sale and drink vending machines for sale. This state-of-the-art machine offers an enhanced user experience, ensuring your business attracts more customers with every purchase.

© 2024 imt. All Rights Reserved.

FOLLOW US:

IMT vending Machine

IMT vending Machine

IMT Vending Machine

IMT Vending Machine