Maintenance and Troubleshooting for Pharma Vending Machines

- Maintenance and Troubleshooting for Pharmaceutical Vending Machines

- Why regular maintenance matters for Pharmaceutical vending machines

- Preventive maintenance checklist for Pharmaceutical vending machines

- Cleaning and sanitation best practices for Pharmaceutical vending machines

- Inventory control and remote monitoring for Pharmaceutical vending machines

- Common faults in Pharmaceutical vending machines and how to troubleshoot them

- 1. Machine won’t power on

- 2. Dispenser jams or failures to release items

- 3. Sensor or touchscreen not responding

- 4. Payment failures

- Software updates, cybersecurity and data integrity for Pharmaceutical vending machines

- Regulatory and controlled-substance considerations for Pharmaceutical vending machines

- Spare parts, service contracts and supply chain best practices

- How IMT supports maintenance and troubleshooting for Pharmaceutical vending machines

- Operational checklist to reduce downtime (quick reference)

- FAQ — Pharmaceutical vending machines

- Contact IMT / See our products

- References

Maintenance and Troubleshooting for Pharmaceutical Vending Machines

Why regular maintenance matters for Pharmaceutical vending machines

Pharmaceutical vending machines distribute medications and medical supplies in hospitals, clinics, pharmacies and workplaces. Because these devices handle controlled items and critical medical products, their reliability, security and hygiene have direct impacts on patient safety, regulatory compliance and operational costs. Regular maintenance minimizes downtime, prevents product spoilage, avoids medication dispensing errors, and reduces the risk of theft or diversion. In short, a structured maintenance and troubleshooting program protects patients, staff and your bottom line.

Preventive maintenance checklist for Pharmaceutical vending machines

Establishing a preventive maintenance (PM) routine is the most effective way to keep pharmaceutical vending machines running. Below is a practical checklist that teams can adopt and adapt to site conditions. Each task should be logged with date, technician initials and any corrective work performed.

- Daily: Visual inspection for obvious damage, verify network connectivity, check temperature (if refrigerated), confirm door/lock operation.

- Weekly: Clean exterior touchpoints, verify sensors and dispensing pathways clear, run a test sale to confirm accurate dispensing and receipt printing (if applicable).

- Monthly: Deep-clean dispensing channels, inspect and lubricate mechanical parts per manufacturer guidance, update inventory reconciliation, check backup battery condition.

- Quarterly: Review software logs, apply minor firmware updates, replace filters (if HVAC or refrigeration present), test remote monitoring alerts and failover systems.

- Annually: Full calibration of scales and sensors, firmware/OS security audit, full preventive replacement of vulnerable wear parts (belts, rollers), and compliance audit for controlled substances handling.

Table: Recommended maintenance intervals and responsible party

| Task | Frequency | Performed by | Source |

|---|---|---|---|

| Visual & connectivity check | Daily | On-site staff | IMT Maintenance Guidelines, 2024 |

| Dispensing pathway cleaning | Weekly–Monthly | Technician / Trained staff | IMT Maintenance Guidelines, 2024 |

| Firmware security updates | Quarterly or as released | IT/IMT Support | IMT Maintenance Guidelines, 2024 |

| Full calibration and compliance audit | Annually | Certified technician / Compliance officer | IMT Maintenance Guidelines, 2024 |

Cleaning and sanitation best practices for Pharmaceutical vending machines

Because pharmaceutical vending machines may contain sterile or sensitive medications, cleaning protocols must prioritize contamination control. Key practices include:

- Use hospital-grade disinfectants compatible with the machine's surfaces. Avoid solvents that damage sensors or screens.

- Establish a schedule for cleaning high-touch areas (touchscreens, payment modules) multiple times per day in clinical settings.

- For refrigerated compartments, defrost and sanitize drip trays regularly. Monitor temperature history to detect deviations that could indicate contamination risk.

- Document all cleaning activities—date, product used, personnel—to support audits and investigations.

These steps reduce cross-contamination, preserve medication integrity and help meet health authority expectations for handling medical products (see References).

Inventory control and remote monitoring for Pharmaceutical vending machines

Modern pharmaceutical vending machines include inventory-management and remote-monitoring features. Proper use of these tools reduces stockouts, prevents overstocking and detects suspicious activity early:

- Real-time stock telemetry: Use live inventory feeds to reorder automatically and run FIFO (first-in, first-out) logistics for medications with expiry concerns.

- Temperature and humidity alerts: For temperature-sensitive drugs, set multi-tier alerts (warning, critical) and integrate with facility alarms or SMS escalation.

- Access logs and audit trails: Track which user ID accessed which product and when. Combine with role-based access to limit high-risk dispensing.

- Analytics: Use dispensing trends to forecast demand and optimize replenishment routes and schedules.

Implementing these practices can cut replenishment costs, improve uptime and support regulatory record-keeping.

Common faults in Pharmaceutical vending machines and how to troubleshoot them

Here are frequent problems operators encounter, with step-by-step troubleshooting guidance that technicians or trained staff can follow:

1. Machine won’t power on

- Check mains power and dedicated circuit breaker.

- Verify internal fuses and external UPS/battery status.

- Inspect for visible cable damage and consult electrical schematics before replacing components.

2. Dispenser jams or failures to release items

- Open the dispensing pathway (following safety and tamper protocols) and clear obstructions.

- Verify correct tray/pusher alignment and that product sizes match configured slots.

- Check sensors and photointerruptors for dust or misalignment; recalibrate sensors if needed.

3. Sensor or touchscreen not responding

- Reboot the control unit to rule out transient software errors.

- Inspect connectors for corrosion; reseat or replace cables.

- If touchscreen calibration is lost frequently, review EMI sources and grounding quality.

4. Payment failures

- Verify network connectivity and payment gateway credentials.

- Update payment terminal firmware and validate PCI compliance requirements.

- Confirm physical card reader cleanliness and alignment.

When a fault persists, capture logs, take time-stamped photos, and contact qualified technical support. Quick, documented escalation reduces downtime and helps identify recurring failure modes.

Software updates, cybersecurity and data integrity for Pharmaceutical vending machines

Because these machines may handle protected health information (PHI) and payment data, cybersecurity is essential. Follow these recommendations:

- Maintain a patch management policy: test and deploy firmware and OS updates in a staged manner to avoid interrupting clinical access.

- Use encrypted communications (TLS) and VPNs for remote access. Disable unused ports and services.

- Implement role-based access controls, two-factor authentication for administrative accounts, and strict password policies.

- Retain and protect logs for auditability; consider write-once storage for critical transaction history.

Regular vulnerability scanning and periodic third-party security assessments help identify gaps before they are exploited.

Regulatory and controlled-substance considerations for Pharmaceutical vending machines

Pharmaceutical vending machines must operate within applicable laws and healthcare standards. Key compliance areas include:

- Controlled substances: Use DEA-compliant storage, access controls, and detailed dispensing logs where required. Integrate with hospital pharmacy systems when necessary.

- Temperature-sensitive drugs: Follow storage and transport guidelines (e.g., refrigerator ranges) and maintain continuous temperature logs for audits.

- Record retention: Store dispensation history and maintenance logs according to local regulations and institutional policies.

Coordinate with your compliance officer to define machine configurations and reporting requirements before deployment.

Spare parts, service contracts and supply chain best practices

Minimizing Mean Time to Repair (MTTR) requires having the right spares and a clear service strategy:

- Stock common wear parts locally (belts, rollers, sensors, door locks) and maintain a recommended spare-parts list provided by your vendor.

- Establish SLA-backed service contracts with defined response times for critical locations, and a clearly documented escalation path.

- Use predictive analytics from remote monitoring to order parts proactively and schedule maintenance windows with minimal patient impact.

How IMT supports maintenance and troubleshooting for Pharmaceutical vending machines

Founded in 2014, IMT is committed to providing customers with customized smart vending machine solutions. IMT has an independent production plant of more than 10,000 square feet and a professional software and hardware development technical team. IMT's vending machines have functions such as automatic vending, remote monitoring, and inventory management. The main products include commercial vending equipment such as smart medical operating room behavior management, smart public health cabins, smart medicine cabinets, smart beverage vending machines, coffee vending machines, etc., and provide supporting equipment control systems, background management system software development, and related after-sales services. The products are exported to more than 100 countries and regions, including the United States, Canada, France, Spain, Germany, Italy, Russia, etc. Our vision is to become the world's leading smart vending machine manufacturer.

IMT’s technical strengths make it a practical partner for healthcare customers seeking robust maintenance and troubleshooting support:

- Integrated remote monitoring: IMT systems provide real-time alerts for temperature, power and dispensing exceptions to reduce MTTR.

- Customizable access control: Role-based and audited user access minimizes diversion risk and supports controlled-substance rules.

- On-site and remote service options: IMT offers service contracts and remote diagnostics to accelerate repairs.

- Global support footprint: Export to 100+ countries ensures the company understands varied regulatory ecosystems.

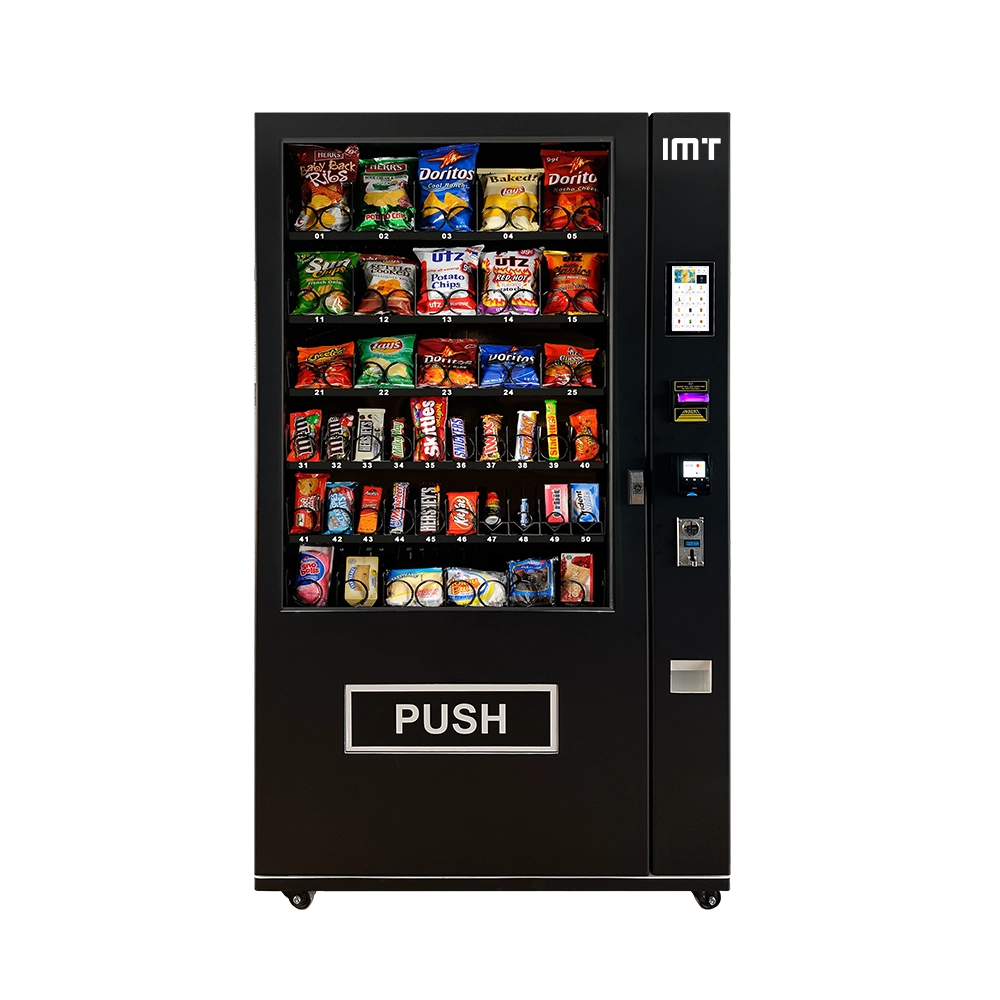

IMT’s main product lines relevant to this guide include Drink & Snack Vending Machine, Beauty & Nail Vending Machine, Locker Vending Machine, Coffee Vending Machine, and Pharmacy Vending Machine. IMT emphasizes modular design, remote telemetry, and strong after-sales support—core competitive advantages that lower lifecycle costs and improve uptime for healthcare deployments.

| Product | Core capability | Maintenance advantage |

|---|---|---|

| Pharmacy Vending Machine | Secure dispensing, inventory logs, refrigerated options | Remote alerts, easy-access modular parts |

| Locker Vending Machine | Secure pickup, PIN/ID access | Minimal mechanical wear, simple lock replacement |

| Coffee & Drink Vending Machines | Heating/refrigeration management, payment integration | Standardized cleaning protocols and replaceable modules |

For more product details and service plans, visit IMT at https://www.imtvending.com/.

Operational checklist to reduce downtime (quick reference)

- Enable remote monitoring during setup and configure alert escalation.

- Train site staff on daily visual checks and basic clearing of jams.

- Sign an SLA for rapid on-site service in critical care areas.

- Document and store maintenance and dispensing logs in a secure, auditable system.

- Schedule quarterly security reviews and annual compliance audits.

FAQ — Pharmaceutical vending machines

Q1: How often should temperature-sensitive compartments be checked?

A: Temperature should be continuously monitored with automated alerts. Verify sensor calibration monthly and perform a full validation at installation and annually.

Q2: Can pharmaceutical vending machines store controlled substances?

A: Yes, but they must meet local controlled-substance storage and access requirements. This typically means secure enclosures, audited access logs and integration with pharmacy inventory systems.

Q3: What is the average response time for critical failures?

A: Response times depend on your service level agreement. For critical clinical locations, plan an SLA with a same-day or 24-hour on-site response.

Q4: How do I prevent repeated dispenser jams?

A: Ensure products are sized and loaded correctly, keep dispensing pathways clean, and replace worn mechanical parts proactively. Use IMT’s modular trays to simplify replacements.

Q5: How are software updates handled without disrupting service?

A: Use staged rollout and maintenance windows during low-usage periods. Test updates on a subset of machines before site-wide deployment.

Contact IMT / See our products

If you need help setting up a maintenance program, want remote monitoring enabled, or are ready to evaluate Pharmacy Vending Machines and other smart vending solutions, contact IMT. Visit https://www.imtvending.com/ to view products, request a quote, or access technical support and service plans.

References

- IMT Maintenance Guidelines and Technical Documentation, IMT (internal), 2024.

- U.S. Food and Drug Administration (FDA), Guidance on Drug Storage and Handling (public guidance documents).

- World Health Organization (WHO), Good storage practices for pharmaceuticals.

- Industry best practices based on IMT field deployments and technical support case studies.

Everything You Need to Know About gourmet coffee vending machine

IMT Best professional coffee vending machine companies manufacturers and supplier brands

Best old snack vending machine manufacturers and supplier brands

Wholesale drink time vending machine manufacturer and supplier

For Customization

Can multiple modifications be made during the customization process?

Yes, during the customization process, we will maintain close communication with customers and allow multiple modifications before the plan is confirmed to ensure that the final design meets customer needs.

Product Details

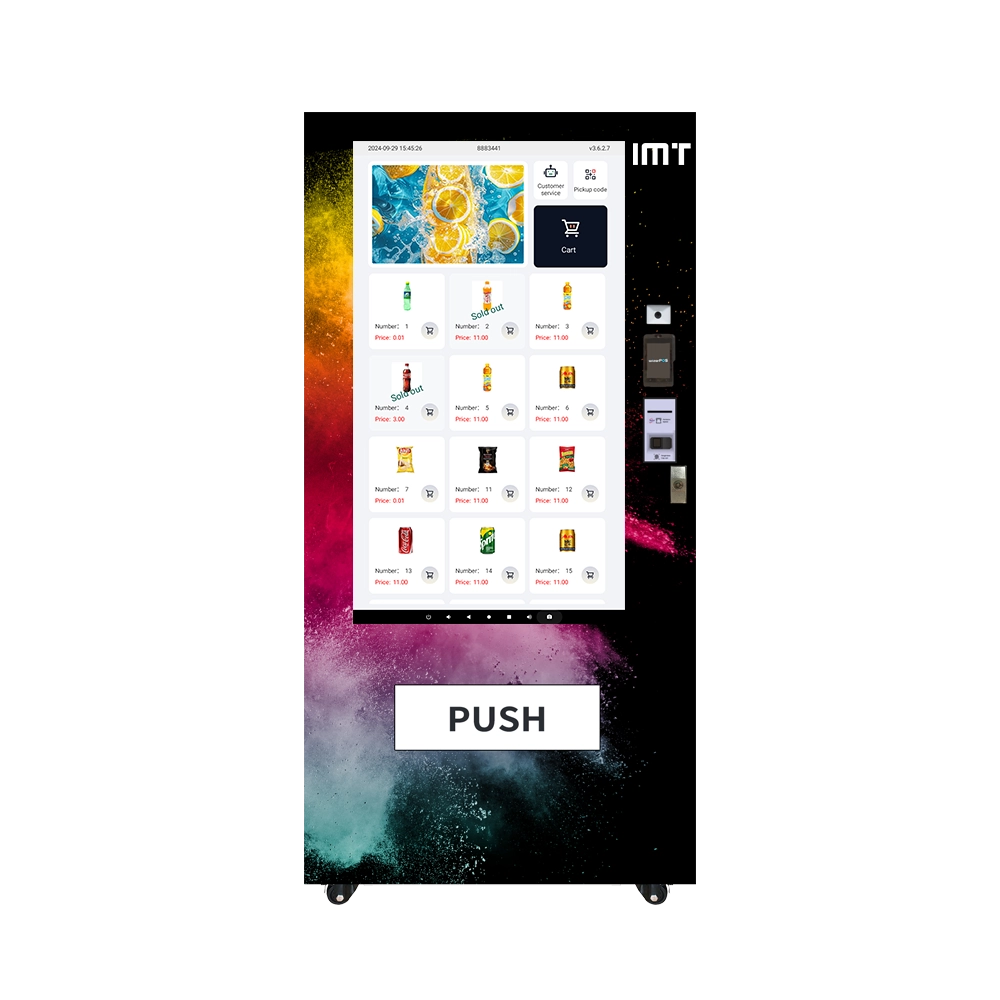

If my agent is a freshman, can he understand the software easily? Can I open subsidiary accounts for my agents or for my remotely operated machines?

Yes, the sales platform is easy to learn and convenient to be operated. It is with real-time sales, stock, profit data and you can control the profit any time and remotely. We have demo and user manual to instruct you step by step opening subsidiary accounts under your own account for your agents or your remotely installed vending machines and monitor these profits.

For Factory

What is the life time of your Vending Machine?

15 years at least.

For Applications

How many machines do you provide? Is there a minimum order quantity?

We provide flexible cooperation options from single machines to large-volume orders. The specific minimum order quantity will be determined according to customer needs and project scale. Please consult our sales team for details.

Is training support provided?

We provide free operation and maintenance training to ensure that customers can master the use of vending machines proficiently.

36 slots Small Screen Metal Keypad Drink Vending Machine

Introducing the IMT 36 Slot Small Screen Metal Keypad Drink Vending Machine. Perfect for any environment, this durable and reliable vending solution provides optimum access to beverages. Explore our range of vending machines for sale, designed to increase convenience and efficiency while improving your customers' refreshment options.

Interactive Touch Screen Vending Machines for Sale – 7.1-Inch Display, 60 Slots, Refrigerated for Drinks & Snacks

Discover the IMT 60 Slot 7.1" Screen Refrigerated Drink Snack Vending Machine, a top choice among snack vending machines for sale and drink vending machines for sale. This state-of-the-art machine offers an enhanced user experience, ensuring your business attracts more customers with every purchase.

21.5-inch Screen Refrigerated Lift Drink Snack Vending Machines with Tray Elevator System

Discover the IMT 60-slot refrigerated drink and snack vending machine. Equipped with a gentle elevator delivery system that ensures product integrity, it allows you to confidently sell a wider variety of goods, including fragile items. Perfect for any location, this machine combines an interactive 21.5-inch display with reliable technology. Explore our advanced touch screen vending machines for sale today and transform your business!

All-in-One Refrigerated Screen Vending Machine: 60 Slots for Drink & Snack

Discover the IMT 60-Slot 55-inch Screen Vending Machine for refrigerated drinks and snacks. Perfect for businesses, this machine keeps products chilled and visible on its large interactive screen. Available for sale now, it's your ultimate solution for convenience and efficiency.

© 2024 imt. All Rights Reserved.

FOLLOW US:

IMT vending Machine

IMT vending Machine

IMT Vending Machine

IMT Vending Machine