How to manufacturing cold drink vending machine for sale in US

- How to Manufacture High-Quality, Sustainable Furniture: A Comprehensive Guide by

- Understanding the Furniture Manufacturing Process: A Step-by-Step Approach

- Sourcing Sustainable Materials: The Foundation of Eco-Friendly Furniture

- Design and Prototyping: Transforming Ideas into Reality

- Manufacturing Techniques: Choosing the Right Approach

- Quality Control and Assurance: Ensuring Excellence

- Skilled Labor and Workforce Management: The Human Element

- Finishing Touches and Packaging: Protecting Your Investment

- Marketing and Sales Strategies: Reaching Your Target Audience

- Pricing Your Products for Profitability: Balancing Cost and Value

- Scaling Your Business: Growth and Expansion Strategies

- Staying Ahead of the Curve: Industry Trends and Innovations

- Frequently Asked Questions (FAQ)

- Q: What are the most sustainable wood choices for furniture manufacturing?

- Q: What is the best way to start a small-scale furniture manufacturing business?

- Q: What software is commonly used for furniture design and prototyping?

- Q: How important is quality control in furniture manufacturing?

- Q: What are some key marketing strategies for furniture businesses?

- Q: How do I determine the right price for my furniture?

- Q: What are some ways to scale my furniture manufacturing business?

- Conclusion: Building a Thriving Furniture Manufacturing Business

How to Manufacture High-Quality, Sustainable Furniture: A Comprehensive Guide by

Understanding the Furniture Manufacturing Process: A Step-by-Step Approach

Manufacturing furniture is a multifaceted process requiring meticulous planning and execution. It involves several key stages, from initial design and material selection to the final assembly and finishing touches. Understanding each step is crucial for producing high-quality, durable, and aesthetically pleasing pieces. This detailed guide will walk you through each stage, helping you build a successful furniture manufacturing business.

Sourcing Sustainable Materials: The Foundation of Eco-Friendly Furniture

Choosing the right materials is paramount, especially if you’re aiming for sustainable furniture manufacturing. This involves considering the environmental impact of your sourcing practices. Prioritize responsibly sourced timber certified by organizations like the Forest Stewardship Council (FSC). Explore the use of recycled materials, such as reclaimed wood, and consider innovative, eco-friendly alternatives like bamboo and rapidly renewable woods. Understanding the lifecycle of your materials and minimizing waste are key components of environmentally responsible furniture manufacturing. The choice of sustainable materials is not just an ethical decision; it's also a smart business strategy, appealing to environmentally conscious consumers.

Design and Prototyping: Transforming Ideas into Reality

Effective design is the cornerstone of successful furniture manufacturing. This involves creating detailed designs, considering ergonomics, and ensuring the manufacturability of your product. Consider using Computer-Aided Design (CAD) software to create precise 3D models and simulations. Prototyping is crucial for testing design concepts, identifying potential issues, and making necessary adjustments before mass production. Investing in robust prototyping will save time, resources, and reduce potential errors down the line. Iterative prototyping ensures the final product meets the highest standards of quality and functionality.

Manufacturing Techniques: Choosing the Right Approach

Several manufacturing techniques are available, each with its advantages and disadvantages. These include traditional methods like handcrafted joinery and more modern techniques like CNC machining. CNC machining offers precision and efficiency for mass production, particularly when dealing with complex designs. However, traditional methods offer a unique aesthetic appeal and often cater to a niche market seeking handcrafted quality. The choice of manufacturing technique depends heavily on the scale of your operation, your target market, and the desired level of customization. Selecting the right approach is crucial for optimizing production costs and maintaining consistent product quality.

Quality Control and Assurance: Ensuring Excellence

Implementing rigorous quality control measures at each stage of the manufacturing process is crucial. Regular inspections, testing of materials and finished products, and employing skilled quality control personnel will minimize defects and ensure consistent product quality. Adhering to industry standards and implementing quality management systems such as ISO 9001 will further improve your processes and build consumer trust. A commitment to quality not only safeguards your reputation but also reduces costly rework and product recalls.

Skilled Labor and Workforce Management: The Human Element

The success of any furniture manufacturing business hinges heavily on its workforce. Investing in training and development for your employees is essential for enhancing skills and improving productivity. Creating a positive work environment that fosters collaboration and encourages creativity will boost morale and improve product quality. Effective workforce management practices, including proper scheduling, fair compensation, and clear communication, are vital for maintaining a motivated and efficient team. Consider implementing lean manufacturing principles to improve workflow and reduce waste.

Finishing Touches and Packaging: Protecting Your Investment

Once the furniture pieces are assembled, they require finishing touches to enhance durability, aesthetics, and protection. This may involve sanding, staining, painting, or applying protective coatings. Choosing the right finishing techniques is essential for preserving the quality and longevity of your furniture. Careful packaging is equally important to safeguard your products during transportation and delivery. Using sustainable packaging materials reflects your commitment to environmental responsibility and further enhances IMT image.

Marketing and Sales Strategies: Reaching Your Target Audience

Effective marketing and sales strategies are crucial for successfully selling your furniture. This includes identifying your target market, developing a strong brand identity, and choosing appropriate marketing channels. Consider utilizing online platforms such as e-commerce websites and social media marketing to reach a broader audience. Participating in trade shows and collaborating with interior designers can further expand your market reach. Understanding your customer base and tailoring your marketing messages to their needs is crucial for achieving sustainable business growth.

Pricing Your Products for Profitability: Balancing Cost and Value

Accurate cost accounting is essential for setting competitive and profitable prices. This involves carefully tracking all expenses, including materials, labor, overhead, and marketing. Understanding your cost structure allows you to determine a price that covers your expenses while ensuring a healthy profit margin. Consider the value your furniture offers to customers, such as its quality, durability, and sustainability features, when determining pricing. Balancing cost and value is crucial for achieving both profitability and customer satisfaction.

Scaling Your Business: Growth and Expansion Strategies

As your business grows, you'll need to implement strategies for scaling your operations. This may involve investing in new equipment, expanding your facilities, and hiring additional personnel. Developing a robust supply chain is also essential for ensuring a consistent supply of materials and meeting growing demand. Careful planning and strategic decision-making are crucial for sustainable business growth and expansion. Explore possibilities for outsourcing certain aspects of your operation to improve efficiency and manage growth effectively.

Staying Ahead of the Curve: Industry Trends and Innovations

The furniture manufacturing industry is constantly evolving. Staying informed about industry trends and technological innovations is crucial for maintaining a competitive edge. This involves attending trade shows, reading industry publications, and networking with other professionals. Embracing new technologies, such as 3D printing and automation, can improve efficiency and create new opportunities. Continuous learning and adaptation are vital for long-term success in the dynamic furniture manufacturing industry.

Frequently Asked Questions (FAQ)

Q: What are the most sustainable wood choices for furniture manufacturing?

A: FSC-certified hardwoods like oak, maple, and walnut are excellent choices. Bamboo and rapidly renewable woods are also highly sustainable options.

Q: What is the best way to start a small-scale furniture manufacturing business?

A: Begin with a niche market and focus on a specific style or type of furniture. Start small, focus on quality, and gradually expand as your business grows.

Q: What software is commonly used for furniture design and prototyping?

A: Popular options include SketchUp, AutoCAD, and Fusion 360.

Q: How important is quality control in furniture manufacturing?

A: It's extremely important. Quality control ensures consistent product quality, reduces defects, and protects IMT reputation.

Q: What are some key marketing strategies for furniture businesses?

A: Utilize online platforms (e-commerce, social media), collaborate with interior designers, and participate in trade shows.

Q: How do I determine the right price for my furniture?

A: Calculate your costs (materials, labor, overhead) and add a profit margin, considering the value proposition of your product.

Q: What are some ways to scale my furniture manufacturing business?

A: Invest in new equipment, expand facilities, hire additional personnel, and streamline your supply chain.

Conclusion: Building a Thriving Furniture Manufacturing Business

Manufacturing high-quality, sustainable furniture requires a meticulous approach, combining artistry with industrial efficiency. By carefully considering each stage of the process, from sourcing sustainable materials to implementing rigorous quality control measures, you can build a thriving and impactful business. Remember to embrace innovation, adapt to industry trends, and prioritize both environmental responsibility and customer satisfaction. With dedication and a keen eye for detail, you can create beautiful, durable furniture while making a positive contribution to the environment and the economy. is here to support you every step of the way.

Where to Buy refrigerated locker vending machine in America

How to start a otc medication vending machine business in US

How to start the free snack vending machine business ?

The instant noodle vending machine manufacturer Cost Guide | IMT Ultimate Insights

For Customization

Can multiple modifications be made during the customization process?

Yes, during the customization process, we will maintain close communication with customers and allow multiple modifications before the plan is confirmed to ensure that the final design meets customer needs.

How long does customization take?

The time for customization will vary depending on the complexity of the project. Generally, the production cycle is 4 to 6 weeks after the plan is confirmed.

How is the customization fee calculated?

The customization fee is evaluated based on factors such as design complexity, material selection and production scale. We will provide a detailed quotation after demand communication.

Product Details

Can you offer white label service and put my brand name (logo) on the vending machines?

Yes, we are capable of providing various kinds of customization services. ODM project is with no MOQ and OEM services with MOQ of 10 PCS.

For Applications

What is the power supply requirement of the machine?

Our vending machines usually require a 220V power supply. Please refer to the product manual for specific power supply requirements. For some models, there may be additional power configuration options.

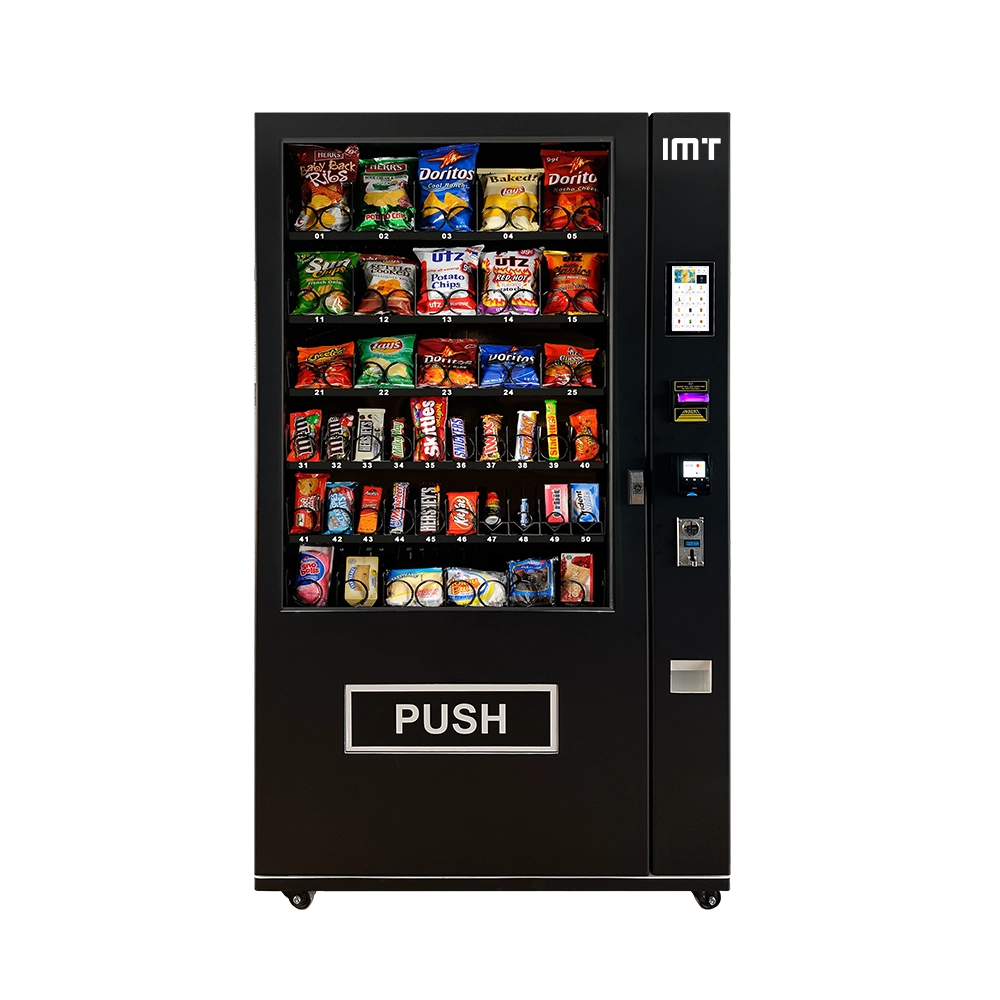

36 slots Small Screen Metal Keypad Drink Vending Machine

Introducing the IMT 36 Slot Small Screen Metal Keypad Drink Vending Machine. Perfect for any environment, this durable and reliable vending solution provides optimum access to beverages. Explore our range of vending machines for sale, designed to increase convenience and efficiency while improving your customers' refreshment options.

Interactive Touch Screen Vending Machines for Sale – 7.1-Inch Display, 60 Slots, Refrigerated for Drinks & Snacks

Discover the IMT 60 Slot 7.1" Screen Refrigerated Drink Snack Vending Machine, a top choice among snack vending machines for sale and drink vending machines for sale. This state-of-the-art machine offers an enhanced user experience, ensuring your business attracts more customers with every purchase.

21.5-inch Screen Refrigerated Lift Drink Snack Vending Machines with Tray Elevator System

Discover the IMT 60-slot refrigerated drink and snack vending machine. Equipped with a gentle elevator delivery system that ensures product integrity, it allows you to confidently sell a wider variety of goods, including fragile items. Perfect for any location, this machine combines an interactive 21.5-inch display with reliable technology. Explore our advanced touch screen vending machines for sale today and transform your business!

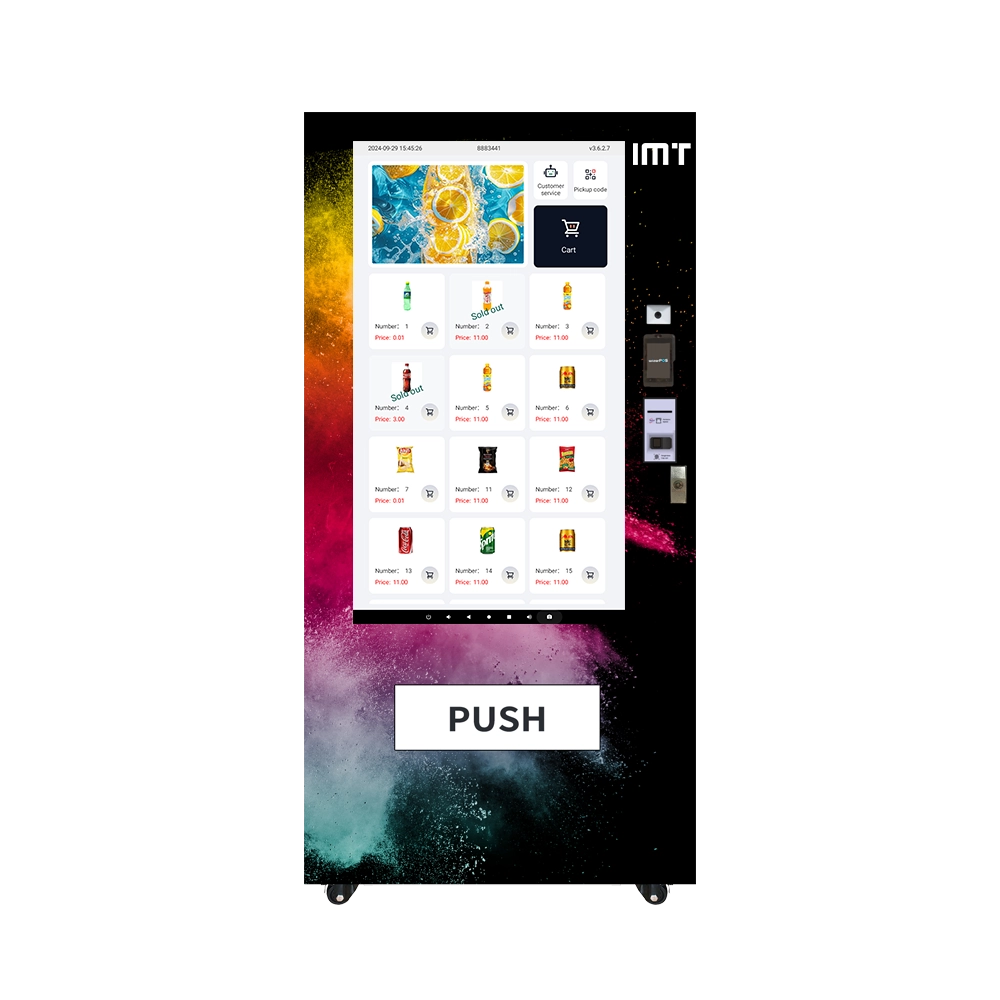

All-in-One Refrigerated Screen Vending Machine: 60 Slots for Drink & Snack

Discover the IMT 60-Slot 55-inch Screen Vending Machine for refrigerated drinks and snacks. Perfect for businesses, this machine keeps products chilled and visible on its large interactive screen. Available for sale now, it's your ultimate solution for convenience and efficiency.

© 2024 imt. All Rights Reserved.

FOLLOW US:

IMT vending Machine

IMT vending Machine

IMT Vending Machine

IMT Vending Machine