Cold Chain Management in Pharmaceutical Vending Machines

- Cold Chain Management in Pharmaceutical Vending Machines

- Why cold chain matters for pharmaceutical vending machines

- Temperature categories and typical pharmaceutical requirements

- Core refrigeration technologies for pharmaceutical vending machines

- Monitoring, sensors and remote telemetry: ensuring visibility into cold chain

- Validation, qualification and regulatory compliance

- Inventory management and traceability in pharmaceutical vending machines

- Risk management and contingency planning

- Operational best practices for pharmacies, clinics and facilities

- Benefits and performance metrics of properly managed cold-chain vending

- Comparison of refrigeration approaches for pharmaceutical vending machines

- Choosing a vendor: what to evaluate in a pharmaceutical vending machine partner

- IMT: smart vending solutions tailored for pharmaceutical cold chain needs

- How IMT’s capabilities align with cold chain requirements

- IMT product overview and core competitive strengths

- FAQ — Frequently Asked Questions

- Contact and product information (CTA)

- References

Cold Chain Management in Pharmaceutical Vending Machines

Why cold chain matters for pharmaceutical vending machines

Pharmaceutical vending machines are transforming access to medicines by offering 24/7 distribution and reducing human errors at point-of-dispense. However, many critical medicines and biologics are temperature-sensitive. Effective cold chain management in pharmaceutical vending machines is therefore essential to preserve potency, comply with regulations, and protect patient safety. Operators must address temperature control, monitoring, inventory integrity, validation, and contingency planning to ensure consistent cold chain performance.

Temperature categories and typical pharmaceutical requirements

Different pharmaceutical products have distinct storage temperatures. Understanding these categories is foundational when designing or selecting vending machines for medicines.

| Temperature Category | Typical Range | Examples | Required Controls |

|---|---|---|---|

| Room temperature | 20–25°C (allowable 15–30°C) | Many oral solids, simple biologics | Insulated cabinet; temperature logging |

| Refrigerated | 2–8°C | Most vaccines, insulin, certain biologics | Active refrigeration, alarms, redundant sensors |

| Frozen | ≤ −20°C | Some vaccines, reagents | Freezer-capable refrigeration, validated freeze control |

| Ultra-cold | ≤ −70°C | Certain mRNA vaccines | Specialized ultra-cold freezers; not typical for vending machines |

Sources for these typical ranges include global public health authorities and pharmaceutical guidance documents (see references).

Core refrigeration technologies for pharmaceutical vending machines

Vending machines designed for pharmaceuticals employ several refrigeration technologies. Each has trade-offs in cost, power consumption, temperature stability and maintenance needs:

- Compressor-based active refrigeration: Reliable for 2–8°C control; common in pharmacy-grade vending machines.

- Thermoelectric (Peltier) cooling: Compact and low-noise but less efficient for larger loads; suitable for small refrigerated compartments.

- Insulation + phase change materials (PCM): Used for passive temperature buffering to maintain temperature during brief power interruptions or during loading.

- Vacuum insulated panels (VIP): Increase thermal performance of cabinets with minimal thickness, improving energy efficiency.

Designers often combine active cooling with high-quality insulation and PCM elements to balance energy use and temperature stability.

Monitoring, sensors and remote telemetry: ensuring visibility into cold chain

Continuous monitoring is non-negotiable. Key elements include:

- Dual redundant temperature sensors placed in critical locations (air space and product level).

- High-frequency logging (e.g., every 1–5 minutes) with timestamped records and secure audit trails.

- Remote telemetry and alerting via cellular/Wi-Fi to notify operators of excursions.

- Integration with cloud dashboards and APIs for centralized fleet management and compliance reporting.

Pharmaceutical vending machines should provide real-time alerts, historical temperature graphs, and the ability to export data for regulatory audits. IMT machines include remote monitoring and inventory management capabilities that meet these operational needs.

Validation, qualification and regulatory compliance

To be accepted for dispensing temperature-sensitive medicines, vending machines must be validated. Typical steps include:

- Design Qualification (DQ): Document specifications for temperature range, alarms, and power continuity.

- Installation Qualification (IQ): Verify installation complies with environmental and electrical requirements.

- Operational Qualification (OQ): Demonstrate the system maintains required temperatures under normal and stress conditions.

- Performance Qualification (PQ): Confirm performance with real product loads and real-world use.

In addition, suppliers should provide calibration certificates for temperature sensors, documented SOPs for temperature excursions, and records suitable for regulatory inspection. Adhering to standards and guidance such as WHO, CDC, FDA and USP documents is essential for compliance.

Inventory management and traceability in pharmaceutical vending machines

Effective cold chain management includes strong inventory controls. Essential features include:

- Lot number and expiry tracking with automated FIFO (first-in-first-out) dispensing rules.

- Secure access control and user authentication for restricted medicines.

- Automated inventory reconciliation and low-stock alerts to prevent stockouts.

- Integration with pharmacy or hospital management systems for record synchronization.

Pharmaceutical vending machines should also support quarantining of product after temperature excursions until quality assessment confirms integrity.

Risk management and contingency planning

Operators must plan for power failures, refrigeration faults, and transport-related temperature excursions. Recommended measures:

- Uninterruptible Power Supply (UPS) or backup battery capable of maintaining controlled temperature for a defined holdover period.

- Automatic lockdown/quarantine routines that prevent dispensing when a product’s storage conditions are suspect.

- Escalation procedures and 24/7 alerting for rapid corrective action.

- Regular preventive maintenance contracts and documented emergency response drills.

Operational best practices for pharmacies, clinics and facilities

To ensure machines function correctly in daily use, operators should adopt these practices:

- Standardize loading procedures: load products from the coldest to warmest areas and minimize door-open time.

- Use temperature-validated packing when transferring stock between storage and machine.

- Train staff on data retrieval, responding to alarms, manual overrides and quarantine workflows.

- Perform daily visual checks and review electronic logs for out-of-range trends.

Benefits and performance metrics of properly managed cold-chain vending

When cold chain is managed well, pharmaceutical vending machines deliver measurable benefits:

- Reduced medicine wastage due to fewer manual handling errors and better inventory control.

- Extended access to care—24/7 dispensing for clinics, long-term care facilities and remote sites.

- Improved compliance and auditability with comprehensive logs and reporting.

Key metrics to track include temperature excursion rates, mean time to recovery after excursions, product wastage percentage, and stockout frequency.

Comparison of refrigeration approaches for pharmaceutical vending machines

The table below compares common refrigeration approaches and their typical suitability for pharmaceutical vending applications.

| Approach | Temperature Control | Power Efficiency | Best Use |

|---|---|---|---|

| Compressor refrigeration | Excellent for 2–8°C and below | Moderate | Standard refrigerated vending for vaccines, insulin and refrigerated medicines |

| Thermoelectric cooling | Good for small compartments; limited capacity | Lower efficiency at scale | Small-volume refrigerated compartments, portable units |

| Insulation + PCM | Buffers transient changes | High (passive) | Supplement to active systems; energy-saving holdover |

Selection should be guided by product profile, dispensing throughput and site power availability.

Choosing a vendor: what to evaluate in a pharmaceutical vending machine partner

When selecting a supplier for pharmaceutical vending machines, evaluate these areas:

- Manufacturing capability and quality systems (ISO certifications, production footprint).

- Technical features: remote monitoring, inventory management, integrated sensors, backup power and alarm systems.

- Software and integrations: APIs, EMR/pharmacy system compatibility, cloud services and data export.

- After-sales support: calibration services, preventive maintenance and spare parts availability.

- International experience and regulatory understanding for your market.

IMT: smart vending solutions tailored for pharmaceutical cold chain needs

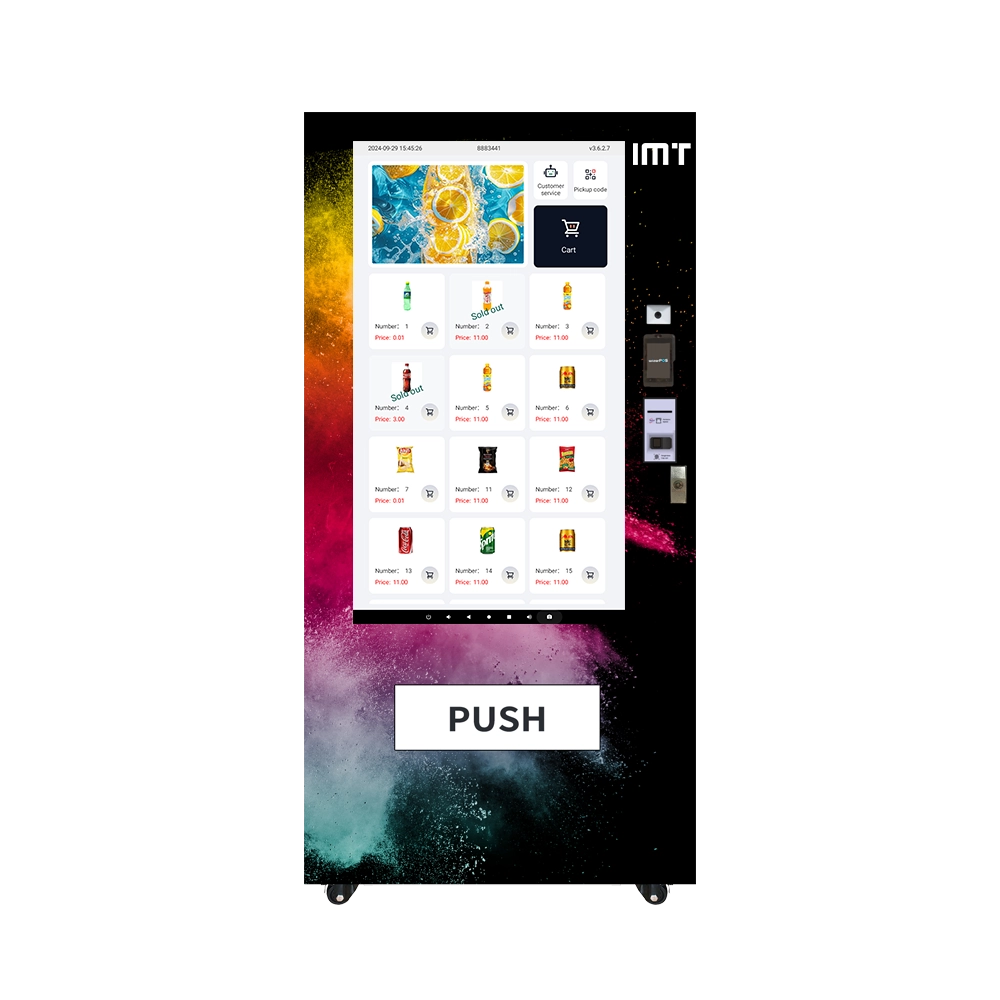

Founded in 2014, IMT is committed to providing customers with customized smart vending machine solutions. IMT has an independent production plant of more than 10,000 square feet and a professional software and hardware development technical team. IMT's vending machines have functions such as automatic vending, remote monitoring, and inventory management.

The main products include commercial vending equipment such as smart medical operating room behavior management, smart public health cabins, smart medicine cabinets, smart beverage vending machines, coffee vending machines, etc., and provide supporting equipment control systems, background management system software development, and related after-sales services. The products are exported to more than 100 countries and regions, including the United States, Canada, France, Spain, Germany, Italy, Russia, etc. Our vision is to become the world's leading smart vending machine manufacturer.

How IMT’s capabilities align with cold chain requirements

IMT’s combined hardware and software expertise supports pharmaceutical cold chain needs in several ways:

- Remote monitoring and telemetry: IMT systems provide continuous temperature logging and real-time alerts to minimize time-to-action on excursions.

- Inventory management and access control: Lot-level tracking and authenticated dispensing ensure traceability and compliance.

- Customizable refrigerated compartments: IMT can deliver compressor-based refrigeration with high-quality insulation and redundant sensors for 2–8°C compliance.

- Manufacturing scale and export experience: A dedicated production plant and global shipping track record support rollout and spare parts logistics.

IMT product overview and core competitive strengths

IMT’s core product categories and competitive advantages include:

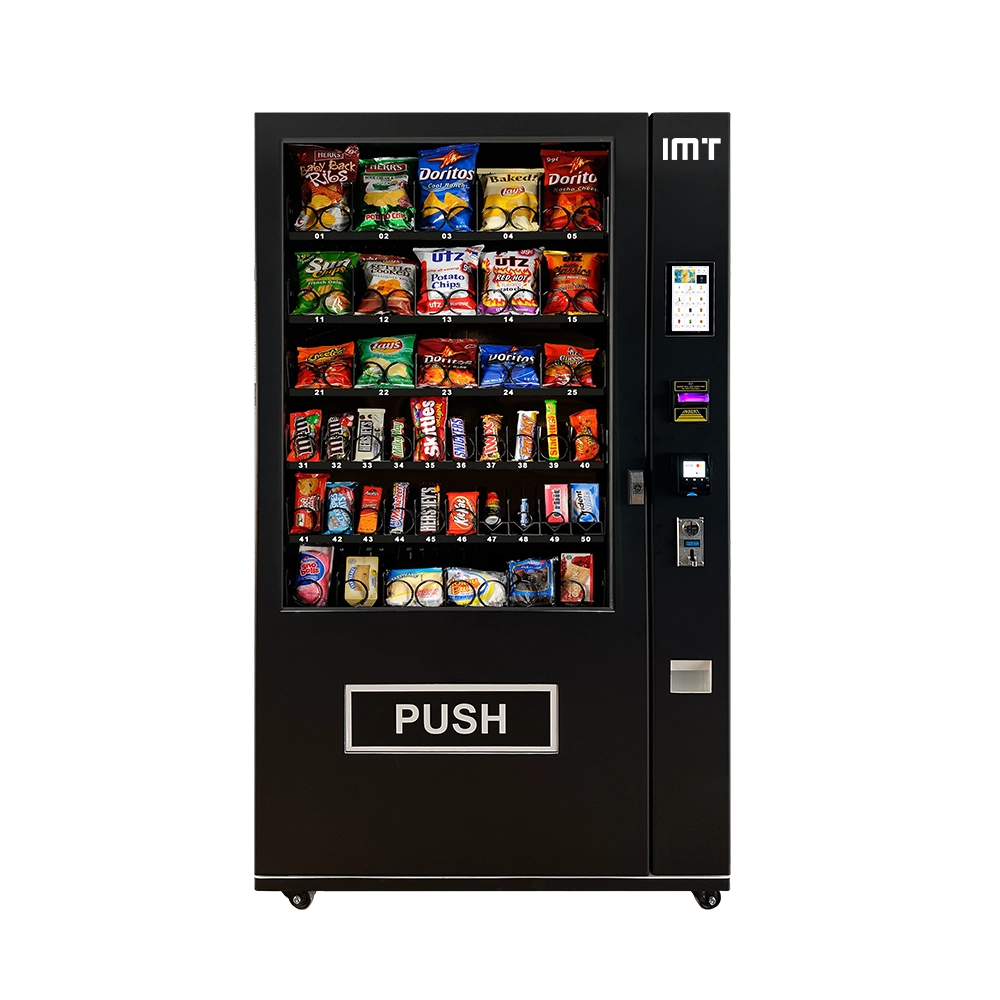

- Drink & Snack Vending Machine — robust designs, energy-efficient refrigeration modules, high uptime.

- Beauty & Nail Vending Machine — controlled environments for cosmetics with temperature-sensitive formulations.

- Locker Vending Machine — secure delivery and pickup solutions suitable for controlled medicines.

- Coffee Vending Machine — reliable hot/cold beverage dispensing with integrated maintenance services.

- Pharmacy Vending Machine — dedicated models for medicine dispensing with refrigeration, authentication, logging, and quarantine workflows.

IMT’s strengths are its integrated hardware/software development team, production capabilities, global distribution experience, and after-sales service network. These strengths make IMT a strong partner for institutions seeking compliant pharmaceutical vending solutions.

FAQ — Frequently Asked Questions

Q: Can pharmaceutical vending machines reliably store vaccines and insulin?

A: Yes—machines designed with compressor refrigeration, validated temperature control (2–8°C), redundant sensors, and continuous logging can reliably store vaccines and insulin. Validation and ongoing calibration are essential.

Q: What happens if a temperature excursion occurs?

A: The machine should immediately alert operators via SMS/email, automatically quarantine affected products, and log the event. Operators must follow SOPs to assess product integrity and disposition based on manufacturer guidance.

Q: Are vending machines suitable for ultra-cold products (≤ −70°C)?

A: Ultra-cold storage typically requires specialized freezers and is not practical for standard vending machines. For −70°C products, dedicated ultra-cold logistics and on-site ultra-cold freezers are recommended.

Q: How often should temperature sensors and systems be calibrated?

A: Calibration frequency depends on local regulations and use, but a common practice is biannual calibration for sensors, with additional checks after any excursion or repair.

Q: Can IMT vending machines integrate with pharmacy management systems?

A: Yes. IMT provides backend management software and APIs for integration, enabling inventory synchronization, audit logs, and centralized remote monitoring across a device fleet.

Contact and product information (CTA)

If you are evaluating pharmaceutical vending machines or need a customized cold chain solution, contact IMT to discuss requirements, request a technical datasheet, or arrange a product demo. Visit https://www.imtvending.com/ to view product lines and contact details. IMT’s team can provide specification sheets, validation support and after-sales service agreements tailored to regulated healthcare settings.

References

- Centers for Disease Control and Prevention (CDC) — Vaccine Storage and Handling Toolkit (updated guidance on recommended storage temperatures and monitoring).

- World Health Organization (WHO) — Cold chain and temperature-sensitive health products guidance.

- U.S. Food and Drug Administration (FDA) — Guidance documents on temperature excursions and stability considerations for pharmaceuticals.

- United States Pharmacopeia (USP) — General chapters and guidance on storage, handling and distribution practices (e.g., USP references related to storage and transportation).

- ISO 13485:2016 — Medical devices — Quality management systems (relevant for suppliers of medical/healthcare equipment).

For additional technical assistance or to request validation documentation for IMT’s Pharmacy Vending Machine models, please contact IMT through the website above.

Where to Buy medication vending machine in Asia

How Much Does a Drink Vending Machine Cost? Your Guide to Smart Investment

Where to Buy jewelry vending machine rings in US

Makeup Vending Machine Price: Cost, Features, and FAQ Guide

For Applications

Does the machine support remote management and monitoring?

Yes, our vending machines are equipped with an intelligent management system that supports remote monitoring and management. Customers can view sales data, inventory status, and machine operation in real time through mobile phones or computers.

For Factory

How about the payment system of the machine?

(1) Cash or coin or card reader

(2) Card reader operating service fees vary in different regions, please inform your location and we will check.

(3) The card reader service fee is charged by the payment system company, and the income by the machine is also directly to the bank card account bound by the machine owner, which is not related to our seller.

Do you inspect the finished products?

Yes, each step of production and finished products will be came out inspection and finished products functional testing by QC department before shipping.

How about the warranty and after-sales services?

The product is guaranteed up to one year from purchased.We have professional after-sales team,About technical problem,our after-sales engineer will reply within 12 hours.

Can you switch according to the language of our country?

Yes, our machine has 85 national languages to switch freely.

36 slots Small Screen Metal Keypad Drink Vending Machine

Introducing the IMT 36 Slot Small Screen Metal Keypad Drink Vending Machine. Perfect for any environment, this durable and reliable vending solution provides optimum access to beverages. Explore our range of vending machines for sale, designed to increase convenience and efficiency while improving your customers' refreshment options.

Interactive Touch Screen Vending Machines for Sale – 7.1-Inch Display, 60 Slots, Refrigerated for Drinks & Snacks

Discover the IMT 60 Slot 7.1" Screen Refrigerated Drink Snack Vending Machine, a top choice among snack vending machines for sale and drink vending machines for sale. This state-of-the-art machine offers an enhanced user experience, ensuring your business attracts more customers with every purchase.

21.5-inch Screen Refrigerated Lift Drink Snack Vending Machines with Tray Elevator System

Discover the IMT 60-slot refrigerated drink and snack vending machine. Equipped with a gentle elevator delivery system that ensures product integrity, it allows you to confidently sell a wider variety of goods, including fragile items. Perfect for any location, this machine combines an interactive 21.5-inch display with reliable technology. Explore our advanced touch screen vending machines for sale today and transform your business!

All-in-One Refrigerated Screen Vending Machine: 60 Slots for Drink & Snack

Discover the IMT 60-Slot 55-inch Screen Vending Machine for refrigerated drinks and snacks. Perfect for businesses, this machine keeps products chilled and visible on its large interactive screen. Available for sale now, it's your ultimate solution for convenience and efficiency.

© 2024 imt. All Rights Reserved.

FOLLOW US:

IMT vending Machine

IMT vending Machine

IMT Vending Machine

IMT Vending Machine